El primer paso en la elaboración del aceite de oliva virgen extra es recolectar el fruto las aceitunas, limpiarlas de hojas y lavarlas. Tras ello, deben prepararse las pastas de la aceituna para posteriormente extraer su jugo a través de las prensas. Las pastas se obtienen mediante el proceso de molturación o molienda que rompe la aceituna, liberando el aceite de los tejidos. La tarea se efectúa a través de varios sistemas. El más común es el molino, sin embargo, desde muy antiguo se emplearon otros sistemas más desconocidos como el de torsión o pisado. A continuación se exponen los procedimientos empleados para la preparación de las pastas. De cada uno de ellos puede obtenerse más información pinchando sobre el enlace o en la fotografía.

SISTEMA DE TORSIÓN

Este procedimiento consiste en introducir las olivas en un saco de tela recia, y ejercer fuerza de torsión enroscándolo con fuerza a través de unas empuñaduras de madera aplicadas en los extremos. Este sistema se constata en el Egipto Antiguo hacia el 2600 a. C.

Fresco de una tumba egipcia de la IV y V Dinastía (2600 a 2300 a. C. en Sakkara) que ilustra el sistema de torsión para obtener aceite de oliva

El sistema de pisado es muy antiguo, su origen se remonta al siglo XX a. C. cuando se atestigua su uso en la sociedad egipcia. Es un procedimiento en el que entran en juego dos elementos: Un recipiente labrado en madera con unas medidas aproximadas de tres metros de largo por sesenta centímetros de ancho; y un saco realizado con elementos vegetales de unos dos metros de longitud. El sistema consistía en llenar el saco con las aceitunas y pisarlo repetidamente con un calzado especial denominado esparteñas o directamente con los pies desnudos. Para trabajar con más firmeza, los obreros podían sostenerse de unas sogas que colgaban del techo. Cuando terminaba esta tarea, se vertía dentro del saco unos tres litros de agua caliente y se volvía a efectuar el pisado. Finalmente se lograba un fluido conformado básicamente por aceite y agua que atravesaba el saco y caía por un lateral de la superficie de madera hasta un recipiente tal y como se muestra en la imagen inferior.

Sistema de pisado de las aceitunas para posteriormente obtener el aceite de oliva virgen

SISTEMA DE PRESIÓN POR RODILLOS: CUBA Y RULOS CILÍNDRICOS

Procedimiento desarrollado durante los siglos V y IV a. C. sobre todo en la zona oriental del Mediterráneo. Se basa en el empleo de cilindros de piedra muy pesados con medidas de dos metros de longitud y unos sesenta centímetros de diámetro. Estos cilindros se hacían rodar, con el auxilio de palancas de madera, sobre cubas de tamaños rectangulares de unos cincuenta centímetros de fondo donde se depositaban las aceitunas. El líquido resultante se escurría por unos orificios situados en la base de la cuba.

SISTEMA DE PRESIÓN CON MAZAS

De este sistema de obtención del aceite de oliva virgen se han hallado restos en el Norte de África. Consistía en aplastar las aceitunas a través de unas mazas de bronce. Algunos investigadores han apuntado que este sistema puede identificarse con el descrito por el autor del siglo I d. C. Columela en su obra "De re rústica" que denomina "Tudicula".

Pastas de la aceituna resultantes de la molturación

Este sistema tiene su origen en la Grecia Antigua y posteriormente se extendió a la Península Itálica y a las colonias romanas. A través de Catón y su obra “De Agricultura” del siglo II a. C. nos llega la primera descripción escrita del “trapetum”. Este autor aseguraba que era una herramienta ideal para moler la aceituna y lograr que el hueso no se rompiera y contaminase el aceite obtenido. El resto de testimonios sobre el "trapetum" nos llegan a través de las fuentes arqueológicas, como por ejemplo los restos encontrados en Pompeya del siglo I a. C. o también en Provenza y África del Norte.

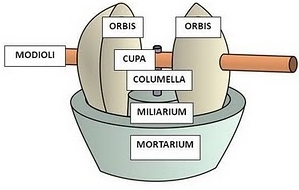

Partes que conforman el "trapetum" romano diseñado para romper las aceitunas y obtener las pastas

A grandes rasgos, el “trapetum” estaba compuesto por un basamento en forma de mortero realizado en piedra denominado “mortarium”; por una columna de piedra o “milliarium” situado en la parte central que permite el movimiento giratorio; y por dos muelas despulpadoras u “orbis” sostenidas por la columna central, de forma plana en su interior y convexas en los lados y que efectúan movimientos giratorios de rotación y traslación. Toda la estructura estaba fijada por placas de hierro y pasadores. Las piedras estaban separadas por una pieza de hierro denominada "alivio" que aportaba el juego suficiente a las mismas y evitaba que apoyaran en el fondo y rompieran los huesos de las aceitunas. Así, a través del rozamiento, se separaba la parte carnosa de la aceituna del hueso.

"Trapetum" romano diseñado para elaborar aceite de oliva virgen extra

MUELA OLEARIA

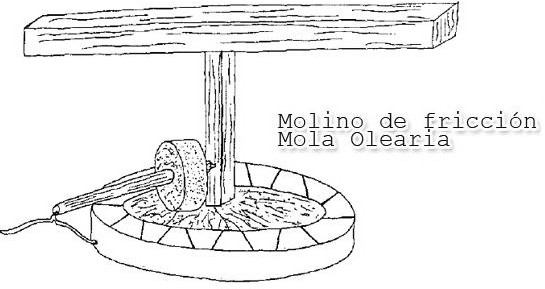

El uso de este sistema es algo posterior al anterior, concretamente se fecha en el siglo I a. C. y es el autor Columela quien nos ofrece su primera mención. Sin embargo, su uso, centrado sobre todo en la zona del Mediterráneo, ha perdurado durante los siglos llegando incluso hasta la actualidad. El objetivo de la mola era similar al “trapetum”: moler la aceituna sin partir los huesos. Esta herramienta estaba compuesta por una peana circular plana o inclinada hacia el centro con un diámetro variable entre 1,40 metros y 2,10 metros. En el centro de la pieza había un agujero de forma circular o cuadrada de profundidad variable en el que se introducía un eje vertical. A este eje vertical se fijaba uno horizontal que atravesaba las muela. La pieza cilíndrica o muela rotaba gracias a la fuerza humana en épocas más antiguas, siendo sustituida por fuerza animal en épocas más recientes.

La "mola olearia" es un molino de fricción ya que rompe las aceitunas gracias a la fricción de la mola con la peana de piedra

Este mecanismo supone una evolución técnica de los sistemas anteriores. Estaba formado por un basamento circular de piedra de más de dos metros de diámetro, elevado medio metro aproximadamente sobre el suelo. Sobre este basamento se asienta la solera. Del centro de ésta, asciende un eje central que suele ser de madera o hierro y que se encaja en una viga sostenida por las paredes del recinto. La molienda se realizaba gracias a la muela que rodaba sobre la solera.

Este modelo de molino fue variando según la muela fuese vertical o troncocónica.

Muela romana para elaborar el aceite de oliva virgen

MOLINO DE RULO

Este molino es una adaptación del anterior y comienza a utilizarse en la Península Ibérica hacia el siglo XVIII. Este es el modelo de molino más tradicional en nuestro país. Estaba compuesto por una gran piedra circular (solera) sobre la que rotaban las muelas fabricadas en piedra con forma troncocónica. Una innovación en este molino fue la introducción de una tolva situada en el centro donde se introducían las aceitunas.

El número de rulos variaba de uno hasta cuatro dependiendo del volumen de producción a atender.

Molino con tres rulos de metal de finales del siglo XIX

El molino de agua es el sistema más reciente de todos los enumerados ya que su uso es posterior al siglo XVII. Ya se había empleado el molino de agua en la molienda del grano y al comprobar su eficacia se aplicó a la aceituna. Este sistema de producción utiliza la fuerza motriz del agua para hacer girar las muelas que rompen las aceitunas originando las pastas que posteriormente serán prensadas para obtener el aceite de oliva virgen extra. Llegado el siglo XIX la fuerza hidráulica será sustituida por la recién nacida fuerza eléctrica haciendo más mecánico el proceso de elaboración del aceite de oliva que hasta entonces, como se ha podido observar a lo largo del texto, había sido más artesano y manual.

El molino de agua es un sistema de obtención de pastas que posteriormente se prensarán para obtener el aceite de oliva virgen extra